Normally customer-oriented, and it’s our ultimate concentrate on for being not only one of the most dependable, trustable and honest supplier, but also the partner for our shoppers for ODM Manufacturer Customize Overseas Engineering Team Technical Support Printing Press Flexo Printer, The continual availability of high grade solutions in combination with our excellent pre- and after-sales services ensures strong competitiveness in an increasingly globalized market place.

Normally customer-oriented, and it’s our ultimate concentrate on for being not only one of the most dependable, trustable and honest supplier, but also the partner for our shoppers for gearless flexo Printing Machine and Paper Printing Machine, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we are going to continue to develop, to supply the high-quality merchandise and services, and promote lasting cooperation with our customers, common development and create a better future.

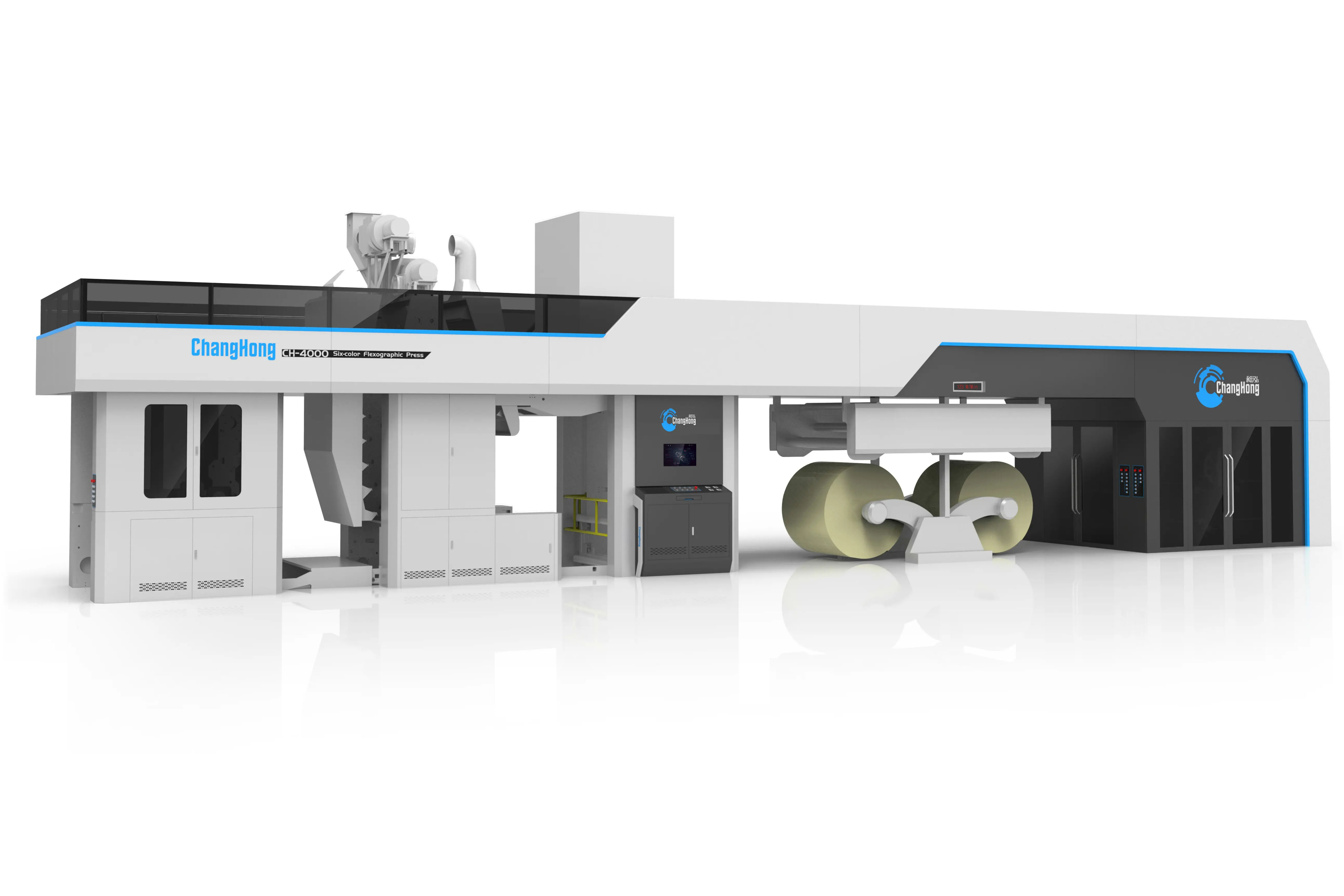

| Model |

CHCI-600F |

CHCI-800F |

CHCI-1000F |

CHCI-1200F |

| Max. Web Width |

650mm |

850mm |

1050mm |

1250mm |

| Max. Printing Width |

520mm |

720mm |

920mm |

1120mm |

| Max. Machine Speed |

500m/min |

| Printing Speed |

450m/min |

| Max. Unwind/Rewind Dia. |

φ1500mm ( Special size can be customized) |

| Drive Type |

Gearless full servo drive |

| Plate thickness |

Photopolymer plate 1.7mm or 1.14mm(or to be specified) |

| Ink |

Water base ink or solvent ink |

| Printing length (repeat) |

400mm-800mm (Special size can be cutomized) |

| Range Of Substrates |

LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, Paper, Nonwoven |

| Electrical supply |

Voltage 380V. 50 HZ.3PH or to be specified |

Normally customer-oriented, and it’s our ultimate concentrate on for being not only one of the most dependable, trustable and honest supplier, but also the partner for our shoppers for ODM Manufacturer Customize Overseas Engineering Team Technical Support Printing Press Flexo Printer, The continual availability of high grade solutions in combination with our excellent pre- and after-sales services ensures strong competitiveness in an increasingly globalized market place.

ODM Manufacturer gearless flexo Printing Machine and Paper Printing Machine, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we are going to continue to develop, to supply the high-quality merchandise and services, and promote lasting cooperation with our customers, common development and create a better future.