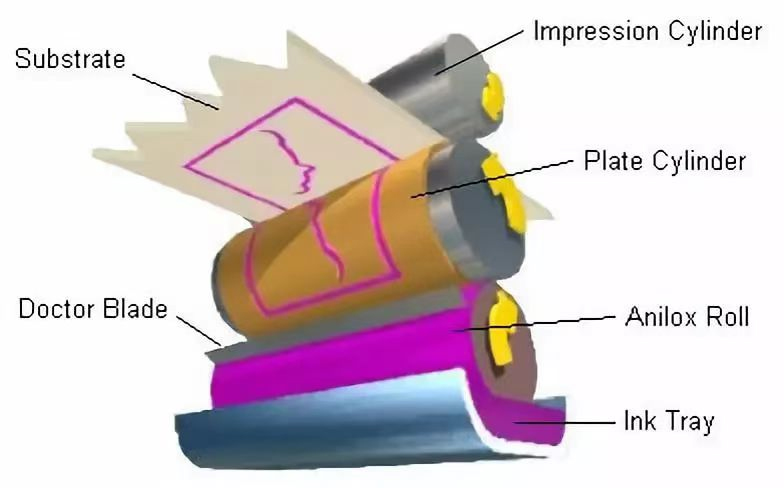

Flexo printer use strong liquidity fluid ink, which spread into the plate by the anilox roller and rubber roller, and then subjected to pressure from the printing press rollers on the plate, the ink is transferred to the substrate, after dry ink the printing finished.

Simple machine structure, therefore easy to operate and maintenance. The price of flexo printer is just about 30-50% of offset or gravure printer.

Strong material adaptability, can get excellent printing performance from 0.22mm plastic film to 10mm corrugated board.

Low printing costs, mainly due to the machine has low plate making costs, low defective percentage during the printing process, and just 30-50% producing cost than the gravure printer.

Good printing quality that can be compared with offset printer and gravure.

It can also called accumulation type of flexographic printer, with 1-8 kinds of color each time, but usually 6 colors.

Advantages

1. Can be printed by monochrome, multicolor or double-sided.

2. Suitable for various materials, such as cardboard, corrugated paper and other hard materials, also roll, like paper label sticker, newspapers, or other materials.

3. The machine has different usage and special advantages,especial for urgent delivery and special printing materials.

4. Attached to many automatic facilities, such as the tension side position, registration and other automatic control system.

5. Small space between each imprint unit, suitable for multi-color high accuracy trademarks, packaging and other small print, overlay effects are good.

Brief introduction: Flexo printing machine, also known as the common impression cylinder flexographic printing press. Each printing unit around a common impression cylinder mounted between two panels, substrates were trapping around the common impression cylinder. Either paper or film, even without the installation of special control system, can still be very accurate. And the printing process is stable, the color used to print product. It has been predicted that the satellite-based flexo will become mainstream of the 21st century.

Disadvantages

(1) Materials through the printer one time can only complete single-sided printing. Since the ribbon is too long , the tensile strain increases, it’s difficult in printing on both sides.

(2) Each printing unit is so near that the ink is easily bad. However, with UV or UV / EB flexo light can achieve instant dry, rub dirty basically solved.

Post time: May-18-2022