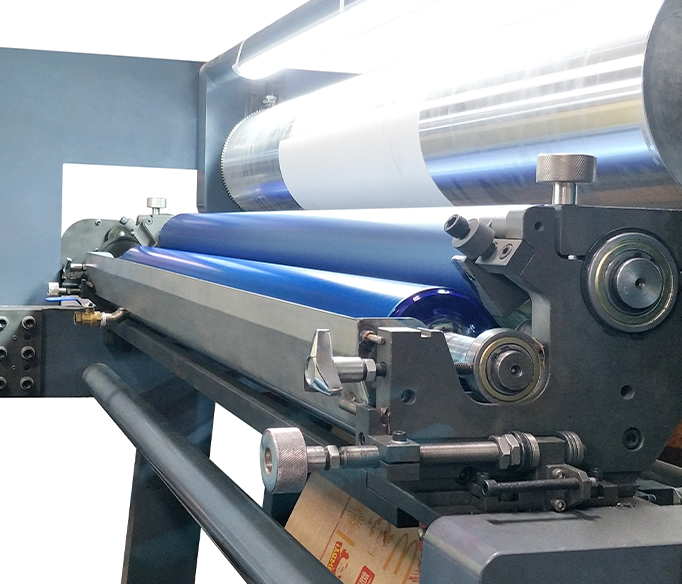

1.The Inline Flexo Printing Machine has strong post-press capabilities. Arranged flexo printing units can facilitate the installation of auxiliary equipment.

2.Inline flexo press In addition to completing multi-color printing, it can also be coated, varnished, hot stamped, laminated, punched, etc. Forming a production line for flexographic printing.

3.Large area and high technical level requirements.

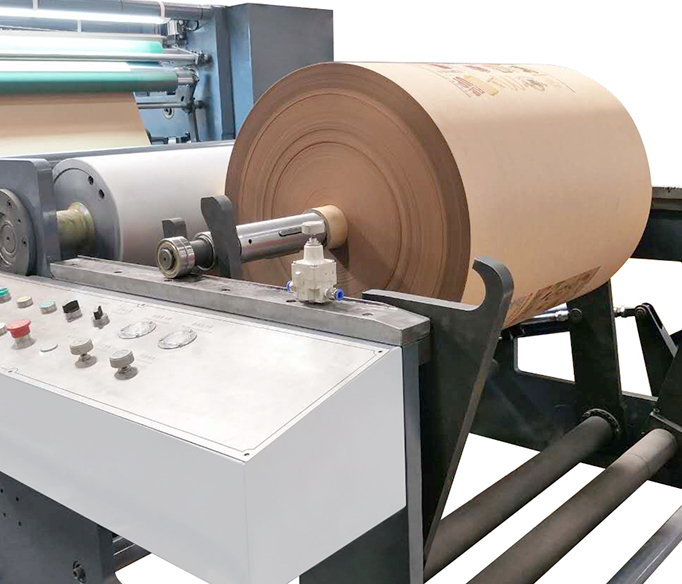

4.It can be combined with a gravure printing machine unit or a rotary screen printing machine as a printing production line to enhance the anti-counterfeiting function and decorative effect of the product.