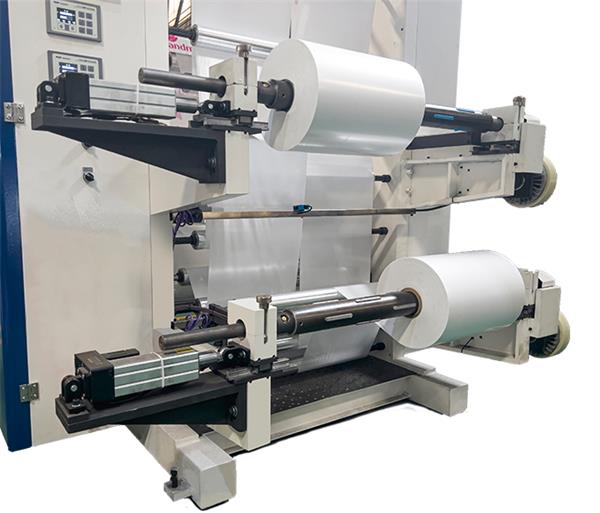

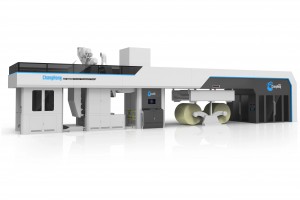

The Double Unwinder & Rewinder Stack Flexo Printing Machine is an advanced piece of equipment that has many impressive features. Here are a few of the noteworthy characteristics of this machine:

1. High-speed printing: The Double Unwinder & Rewinder Stack Flexo Printing Machine can reach speeds of up to 120 meters per minute, making it a highly efficient printing solution.

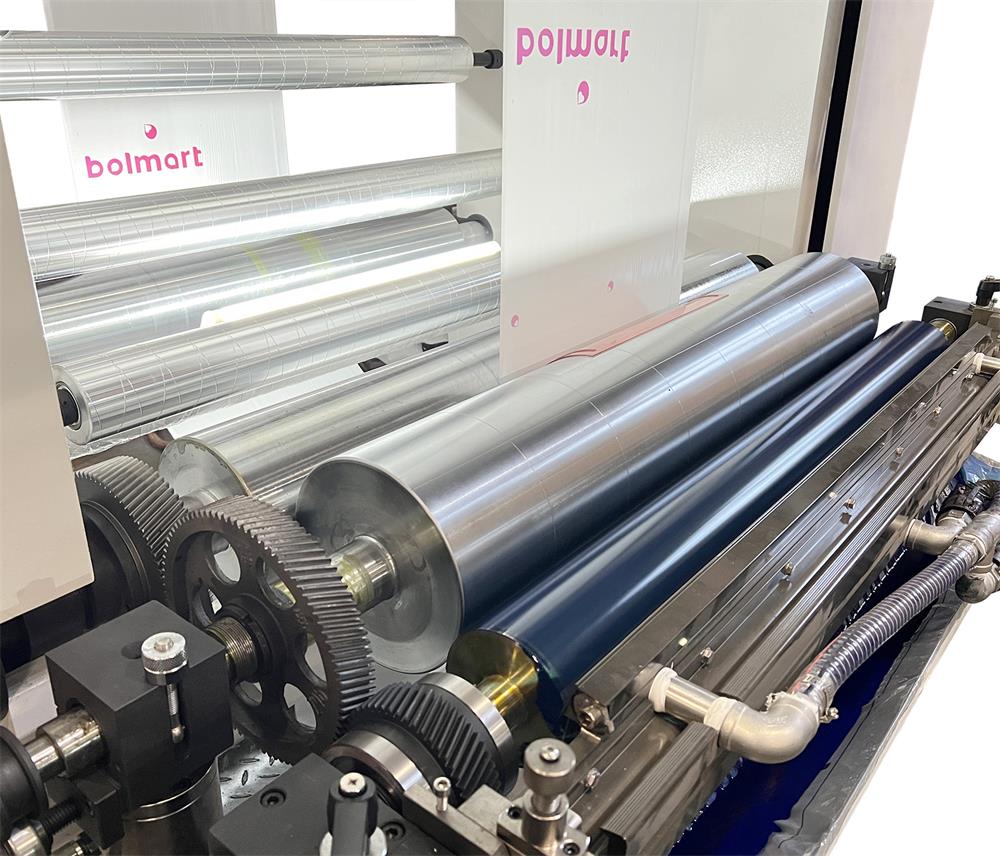

2. Accurate registration: This machine uses advanced technology to ensure that the printing is accurate and consistent. The registration system ensures that each color is printed in the correct position, resulting in a sharp and precise image.

3. LED drying system: The Double Unwinder & Rewinder Stack Flexo Printing Machine uses an energy-efficient LED drying system that is both eco-friendly and cost-effective.