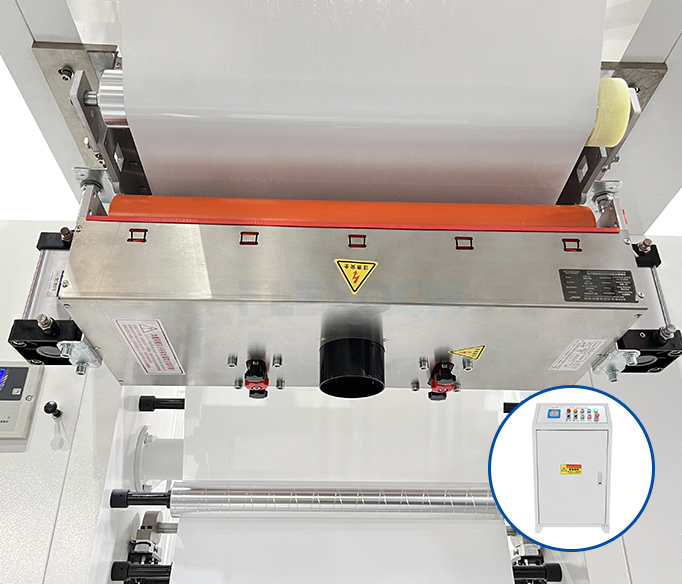

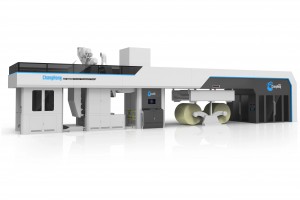

1.This stack type flexo printing machine integrates an innovative corona pretreatment system to optimize the surface energy of materials in real time, accurately overcome the adhesion problem of non-polar substrates such as PE, PP, and metal foil, ensure the ink is firmly attached during high-speed printing, eliminate the hidden dangers of de-inking and stratification, and take into account the environmental advantages and industrial-grade stability of flexographic printing.

2.The modular design of the stack type flexo printing press is suitable for multiple scenarios, from food-grade films to pharmaceutical composite packaging, from environmentally friendly inks to UV special printing, and can respond quickly. The compact stacking structure saves plant space, the intelligent pre-registration and quick-change system shortens the order switching time, and combined with the local corona enhancement module, it can easily cope with the fine process requirements such as anti-counterfeiting labels and high-gloss coatings.

3.The stack flexographic printing machine has the long-term value of intelligent central drive. The system monitors the entire printing process in real time, independently optimizes corona parameters and production rhythm, and collaborates with historical process data in the cloud to reduce debugging costs and energy waste. Empowering decision-making with data, helping enterprises achieve green intelligent manufacturing upgrades and continue to lead in the packaging printing track.