- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

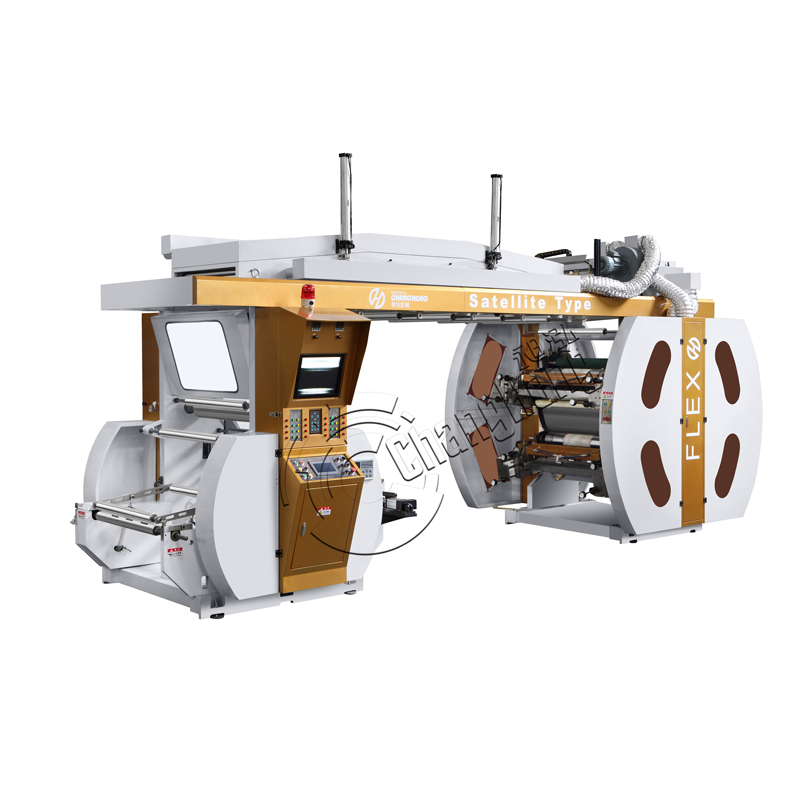

China wholesale Ceramic Printing Machine Manufacturer – 6 Colour Stack Type Flexo Printing Machine – Changhong Printing

China wholesale Ceramic Printing Machine Manufacturer – 6 Colour Stack Type Flexo Printing Machine – Changhong Printing

China wholesale Ceramic Printing Machine Manufacturer – 6 Colour Stack Type Flexo Printing Machine – Changhong Printing Detail:

| Model | CH-600H | CH-800H | CH-1000H | CH-1200H |

| Max. Web Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Printing Width | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 120m/min | |||

| Printing Speed | 100m/min | |||

| Max. Unwind/Rewind Dia. | φ1000mm or φ1200mm( can according to your requirement) | |||

| Drive Type | Gear drive/Belt Drive( According to your requirement) | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 270mm-900mm | |||

| Range Of Substrates | PAPER,NON WOVEN | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or as your requirement to make it | |||

1. Unwind unit adopts single-station or double-station structure; 3″air shaft feeding; Automatic EPC and constant tension control;With refueling warning, break material stop device.

2. The main motor is controlled by frequency conversion, and the whole machine is driven by high-precision synchronous belt or servo motor.

3. The printing unit adopts ceramic mesh roller for ink transfer, single blade or chamber doctor blade, automatic ink supply; Anilox roller and plate roller automatic separating after stop; The independent motor drives the anilox roller to prevent ink from solidifying on the surface and blocking the hole.

4. Rewinding pressure is controlled by pneumatic components.

5. Rewind unit adopt single-station or double-station structure; 3 “air shaft; Electric motor drive, with closed – loop tension control and material – breaking stop device.

6. Independent drying system: electric heating drying (adjustable temperature).

7. The whole machine is centrally controlled by PLC system; Touch screen input and display the working state; automatic meter counting and multi – point speed regulation.

1. Polyethylene, polyethylene plastic film printing

2. Bag(packing bag for food, supermarket handbag, vest bag and clothes bag printing

3. Roller paper and craft paper printing

4. PP woven bag , pvc film, bopp film, printing

5. Laminated bag rolling printing

6. Non woven rolling printing

7. Rice bag pp woven printing

8. Paper printing

Product detail pictures:

Related Product Guide:

Our commission should be to provide our end users and clients with very best excellent and aggressive portable digital products and solutions for China wholesale Ceramic Printing Machine Manufacturer – 6 Colour Stack Type Flexo Printing Machine – Changhong Printing , The product will supply to all over the world, such as: Sweden, London, South Africa, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information and we will offer you competitive price list then.