- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

Best High Quality Letterpress Machine Factories – Paper/Paper bag /flexo printing machine – Changhong Printing

Best High Quality Letterpress Machine Factories – Paper/Paper bag /flexo printing machine – Changhong Printing

Best High Quality Letterpress Machine Factories – Paper/Paper bag /flexo printing machine – Changhong Printing Detail:

Each printing group of the Inline flexo press is arranged horizontally and linearly independently, and a common drive shaft can be used to drive the Inline flexo printing machines. This series of flexo printing machines can print on both sides. Suitable for printing on paper materials.

The following is the printing process of In line flexo printing machine.

|

CH6-1200A Series (Printing material:PAPER)-6 color |

|

|

Model |

CH6-1200A |

|

Maximum winding and unwinding diameter |

ф1524 |

|

Inner diameter of paper core |

3″OR 6″ |

|

Maximum paper width |

1220MM |

|

Repeat length of printing plate |

380-1200mm |

|

Plate thickness |

1.7mm or to be specified |

|

Thickness of plate mounting tape |

0.38mm or to be specified |

|

Registration accuracy |

±0.12mm |

|

Printing paper weight |

40-140g/m2 |

|

Tension control range |

10-50kg |

|

Maximum printing speed |

100m/min |

|

Maximum machine speed |

150m/min |

1.The flexo printing machine can perform double-sided printing by changing the conveying route of the substrate.

2.The printing material of the printing machine is a single sheet of paper, kraft paper, paper cups and other materials.

3.There are many working stations in the unit, and one machine can be used for multiple purposes.

4.It has the advantages of strong post-press processing ability and strong variability.

5.The raw paper unwinding rack adopts single-station air expansion shaft automatic unwinding method.

6.The tension is taper control technology to ensure the accuracy of overprinting.

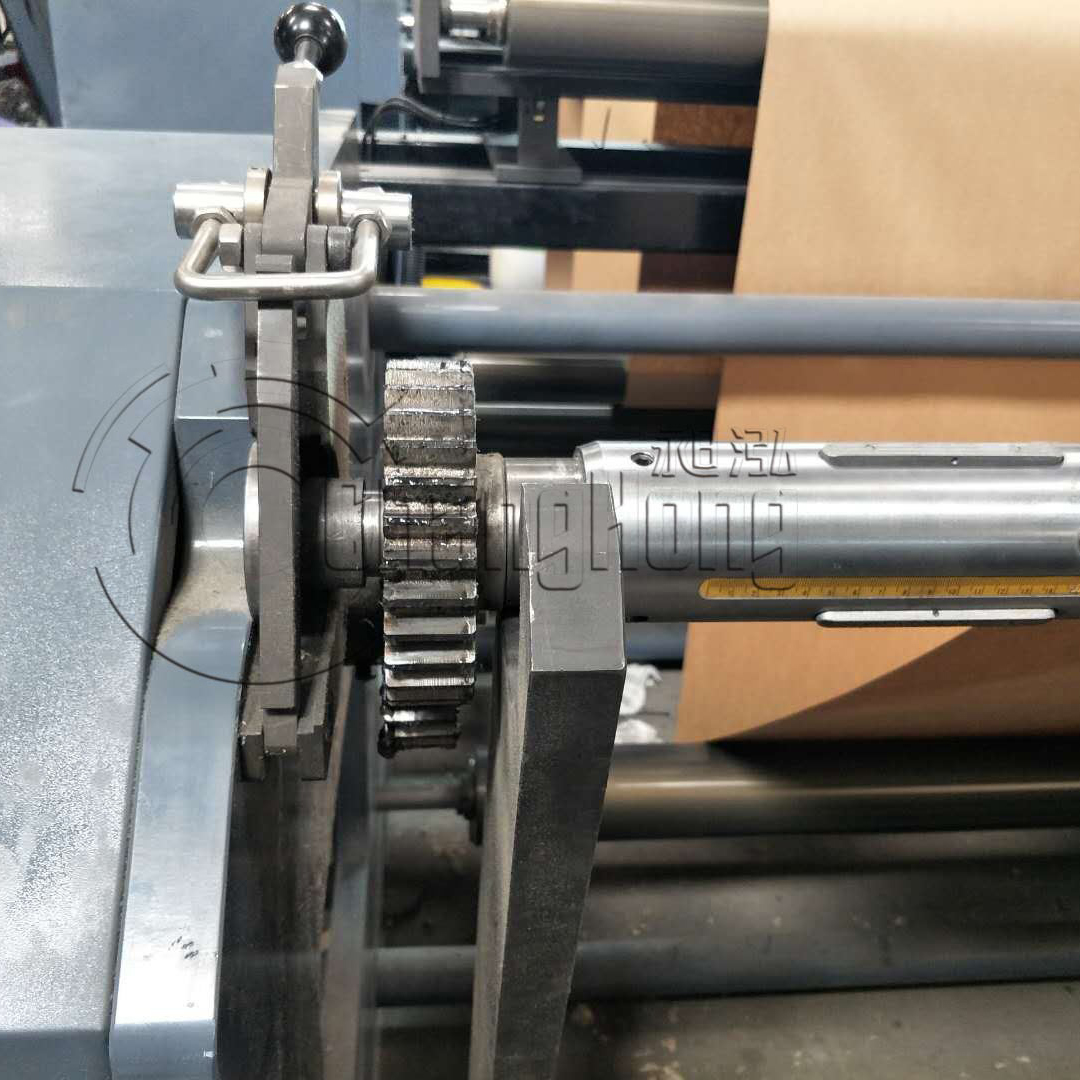

7.The printing unit adopts an integral alloy cast iron double wall panel and a 45-degree helical gear transmission structureDrive method: Gear Drive.

8.The winding is driven by a motor, and the floating roller structure realizes closed-loop tension control.

CE,ISO9001.

Product detail pictures:

Related Product Guide:

Our pursuit and company goal is to Always satisfy our customer requirements. We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for Best High Quality Letterpress Machine Factories – Paper/Paper bag /flexo printing machine – Changhong Printing , The product will supply to all over the world, such as: Sevilla, California, Houston, Many years of work experience, we have now realized the importance of providing good quality products and solutions and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .